Bag Filter Capacity Calculation

Bag filter capacity calculation. F gas flow at 25 C given in m3min c concentration of dust given in gm3 φ average diameter of the particle in μm For example con F700 m3min c 40 gm3 φ 50 μm. Step 1Select the type of bag micron rating and flow rate determine the pressure drop for water 1 cps 68F for a size 2 bag. In di-ameter by 4 to 5 ft.

Select the bags dimension usually 1506000 mm and then you are ready to get the results of fabric bag filter design calculator. 115 lbs125 lbshr 92 hours The above calculations depicted in Figure 2 on the next page demonstrate how filter change-out time can be increased by over 14 times 92 vs. To determine the appropriate filter size we must study the air.

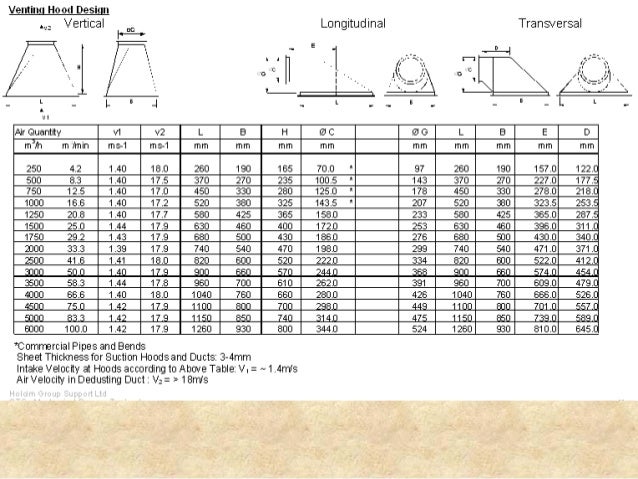

The design engineers must determine the following. From these charts we find the bag should be 20 in. Then Click on Calculate To Find the Interstitial Velocity.

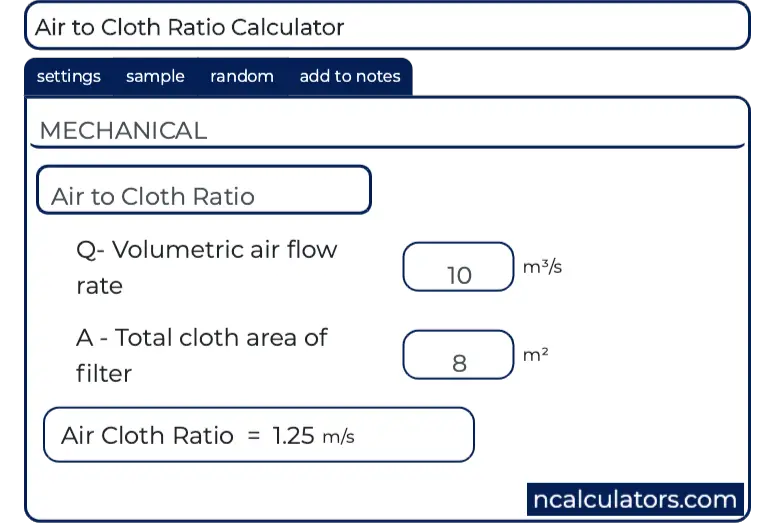

Volume occupied by the filter m3 033 SF. Take the CFM of the system and divide it by the total filter cloth area to get your air to cloth ratio. The filtering surface SF given in m2 is estimated using the following expression.

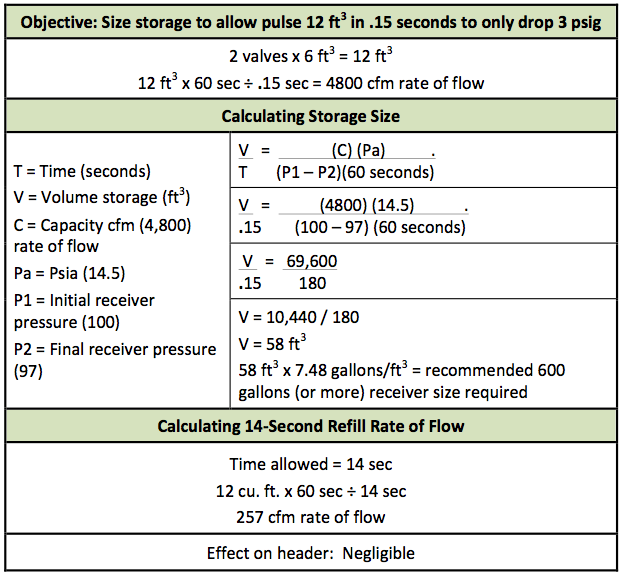

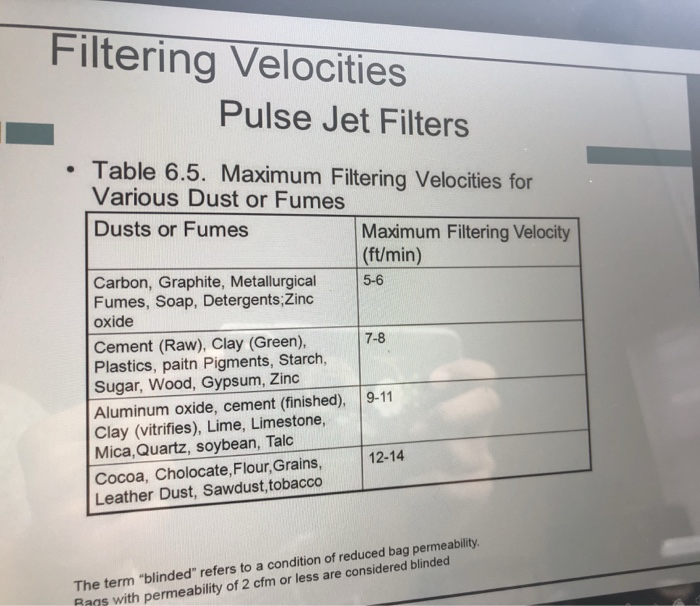

Step 2 Correct the bag size from the table below if the bag filter size is not 2. Special bag treatments or corrosion-proof coatings on structural components. PULSE JET BAG FILTER DESIGN Where.

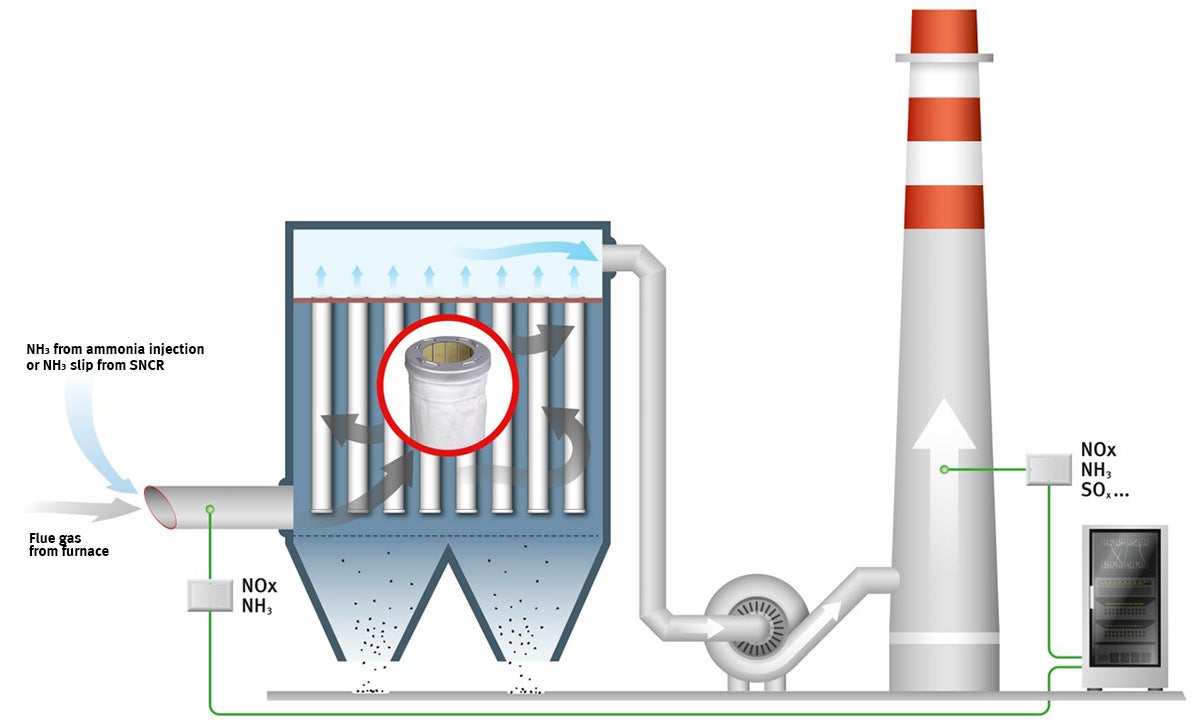

Test bag filters were made of polyester fabric and had a 156 mm diameter and a 3 m lengthThe cleaning interval of the pulse-jet cleaning system and the effects of inlet particle concentration with various can velocities were considered. 23 lbs Total Dirt Holding Capacity. Woven or felt filters filter thickness fiber size fiber density filter treatments such as.

Step 2Correct for bag size from the Bag Size Correction. 133 m3 for the example.

Bag Size Dimensions Dia x Length in Correction factor 2 706 x 32 100 9 55 x 32 150 1 706 x 16 225 8 55 x 21 225 7 55 x 15 300 4 415 x 14 450 3 415 x 8 900 Step 3 If the viscosity of the liquid is greater than 1.

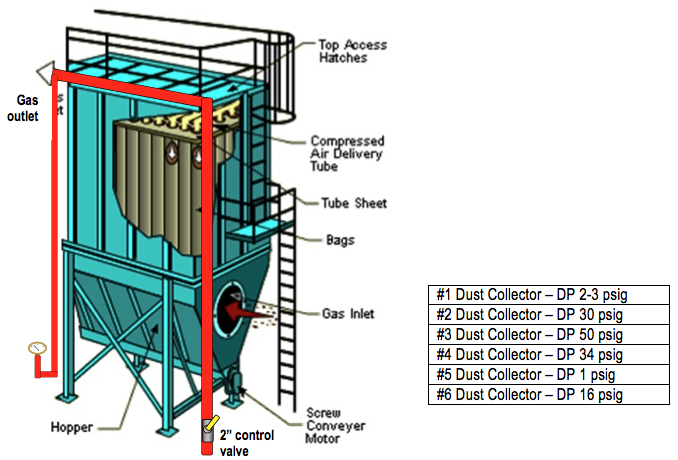

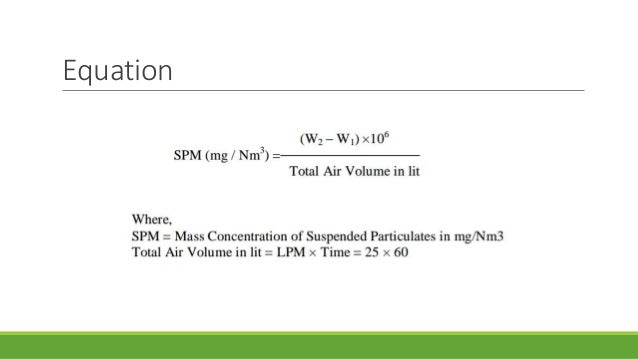

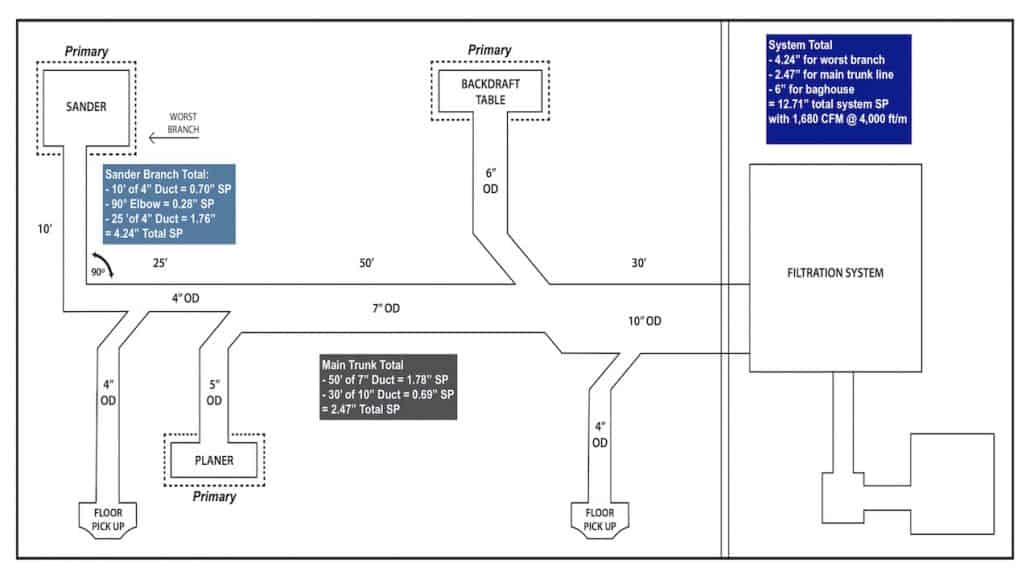

Select the bags dimension usually 1506000 mm and then you are ready to get the results of fabric bag filter design calculator. The design engineers must determine the following. Enter ACFM of Air Side L in Side w in - Bag Dia2² π of Bags. 02 28112008 ISO 90012000 4 DESCRIPTION OF COMPONENTS 41 Filtering Bags These are filtering elements made in needled felt through which the air and dust separation takes place as the air. Volume occupied by the filter m3 033 SF. 8000cfm air required for dust control Kice VR96-10 Filter offers 4343ft² of open area between bags 8000cfm 4343ft² open area 1842fpm interstitial velocity. Bag filter design calculation xls. Test bag filters were made of polyester fabric and had a 156 mm diameter and a 3 m lengthThe cleaning interval of the pulse-jet cleaning system and the effects of inlet particle concentration with various can velocities were considered. Woven or felt filters filter thickness fiber size fiber density filter treatments such as.

F gas flow at 25 C given in m3min c concentration of dust given in gm3 φ average diameter of the particle in μm For example con F700 m3min c 40 gm3 φ 50 μm. Then Click on Calculate To Find the Interstitial Velocity. 23 lbs Total Dirt Holding Capacity. Look for a bag that will handle 1200 to 1600 CFM maximum or 750 to 1000 CFM working under load output. 23 lbs x 5 115 lbs Filter Run Time. F gas flow at 25 C given in m3min c concentration of dust given in gm3 φ average diameter of the particle in μm For example con F700 m3min c 40 gm3 φ 50 μm. 115 lbs125 lbshr 92 hours The above calculations depicted in Figure 2 on the next page demonstrate how filter change-out time can be increased by over 14 times 92 vs.

Posting Komentar untuk "Bag Filter Capacity Calculation"