Pulse Jet Baghouse Design

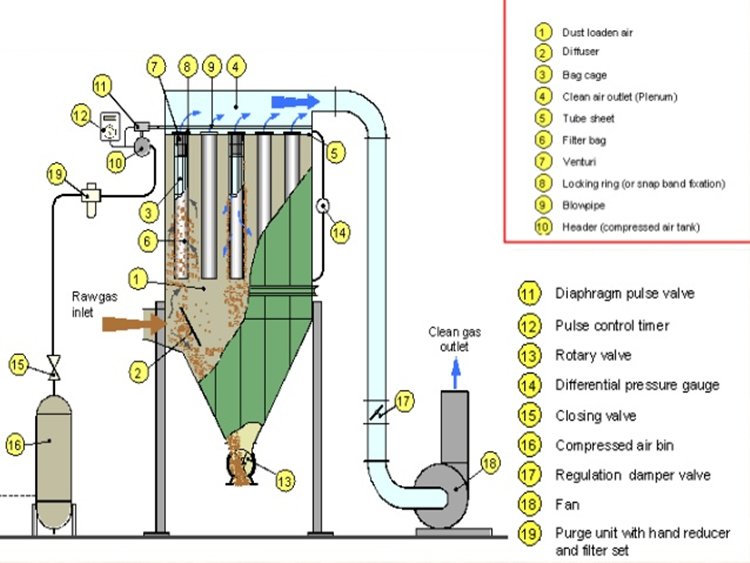

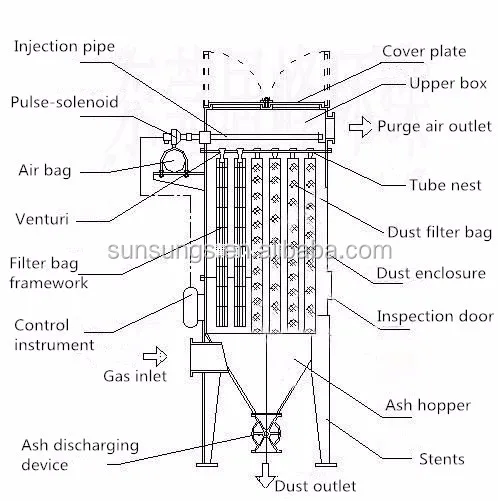

Pulse jet baghouse design. This baghouse design is typically applied to filter gas volumes greater than 140000 ACFM and up to 25. Where baghouses larger than typical pulse jets are required they are often custom-built reverse-air units. Design considerations for a pulse-jet baghouse Physical and chemical properties of the dustare extremely important for selecting the fabric that will be used.

Heres a brief overview on the pros and cons of each to help guide you in identifying. A thorough review of baghouse design plans should consider the following factors. The LCM pulse jet bag filter produced by AGICO is a new type and efficient dust collector developed by our technicians on the basis of the fabric filter.

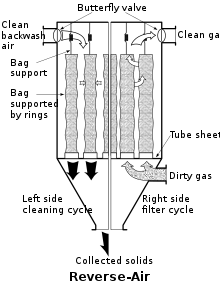

Average and maximum concentrations. The pulse-jet baghouses have become popular because they occupy less space than the equivalent shaker baghouse and are perceived as being less expensive. There are three main styles of baghouses eg.

A thorough review of baghouse design plans should consider the following factors. It is one of our hot sales cement dust collectors. This parameter is important because higher pressure drop means higher.

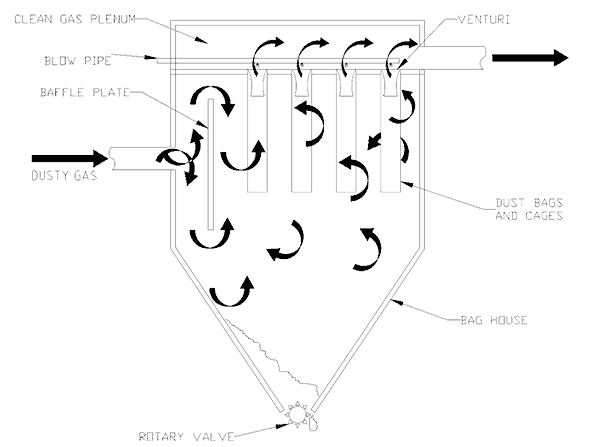

The combination of a low-velocity inlet with a baffle for even dust distribution and the vertical bag configuration that easily sheds dust makes the Pulse Jet Baghouse an efficient dust control solution. Changes to any of these key sys-tem parameters will result in systemwide perform- ance issues. Lower maintenance and energy costs over time than traditional shaker style baghouses We engineer and manufacture industrial pulse jet baghouse dust collection systems for a broad micron range of dust applications.

These include size type shape and density of dust. Pleated Element Pulse Jet Baghouse For applications requiring 211 to 1960 ft2 of cloth area per unit with 20 40 54 long filters. Average and maximum concentrations.

The pulse-jet type fabric filter is the leader of the baghouse technologies. To ensure consistent performance we have tuned our pleated collectors around OEM filter characteristics.

Chemical and physical properties such as abrasiveness.

Schust LIBERATOR Pleated Element Baghouse provide an industry leading design. The modular design simplifies application up to. A thorough review of baghouse design plans should consider the following factors. Pulse jet bag filter is also called pulse jet fabric filter pulse jet baghouse or pulse jet dust collector. Felt used for under 400. There are three main styles of baghouses eg. This Pulse-Jet baghouse design can accommodate 6 meter to 10 meter long filter lengths ranging from 535 dia up to 6 dia and 2-piece cages. Design considerations for a pulse-jet baghouse Physical and chemical properties of the dust are extremely important for selecting the fabric that will be used. Pleated Element Pulse Jet Baghouse For applications requiring 211 to 1960 ft2 of cloth area per unit with 20 40 54 long filters.

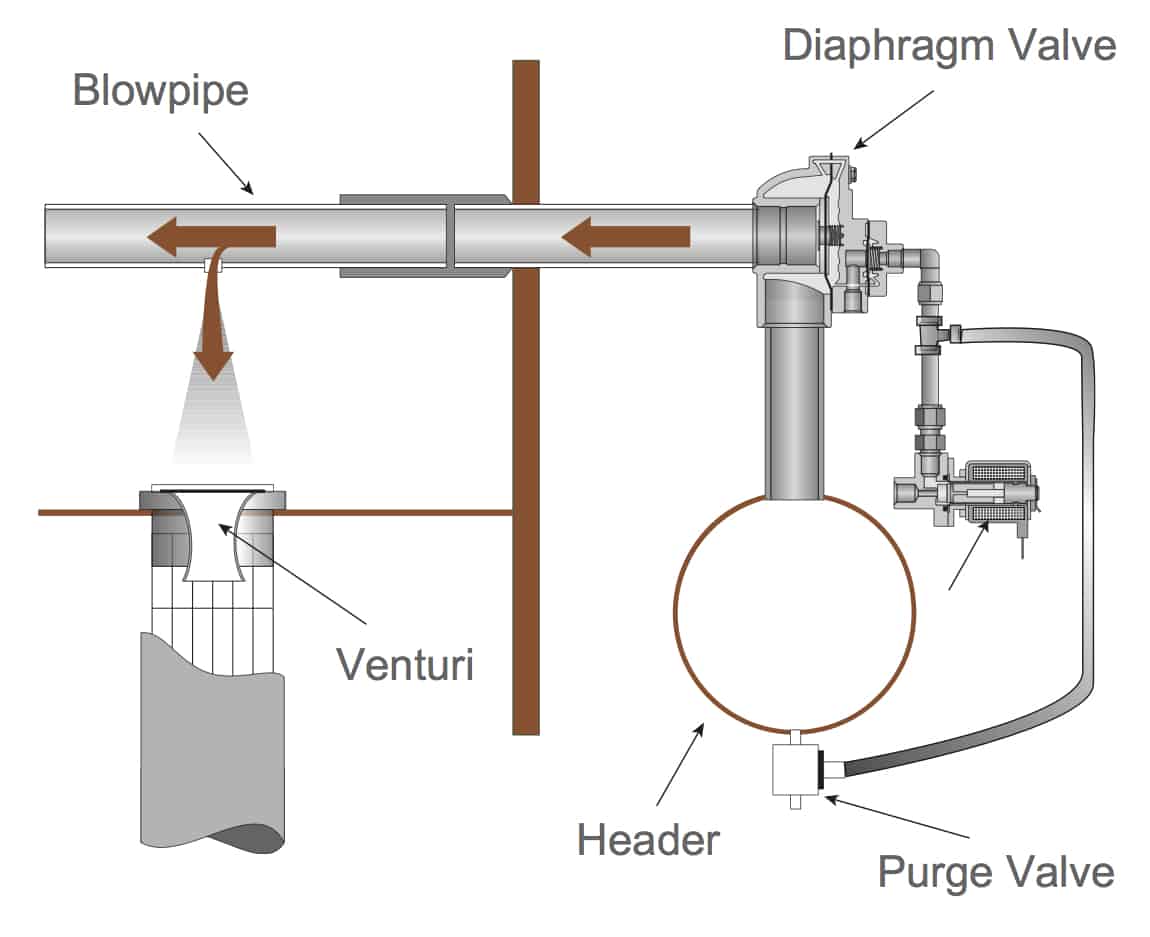

In these environments a baghouse will handle and most efficiently filter your dust laden air. These include size type shape and density of dust. Design considerations for a pulse-jet baghouse Physical and chemical properties of the dustare extremely important for selecting the fabric that will be used. This baghouse design is typically applied to filter gas volumes greater than 140000 ACFM and up to 25. The M-Pulse is especially effective on coal fired biomass and other steam production applications. The resulting air wave pops the bags away from the cage. To ensure consistent performance we have tuned our pleated collectors around OEM filter characteristics.

Posting Komentar untuk "Pulse Jet Baghouse Design"